Adjustable is a lifelong modular furniture system constructed from reclaimed pine floorboards. These floorboards are sourced from reclaim yards around London. Many of these boards tend to be from Edwardian or even Victorian homes, making them over 100 years old.

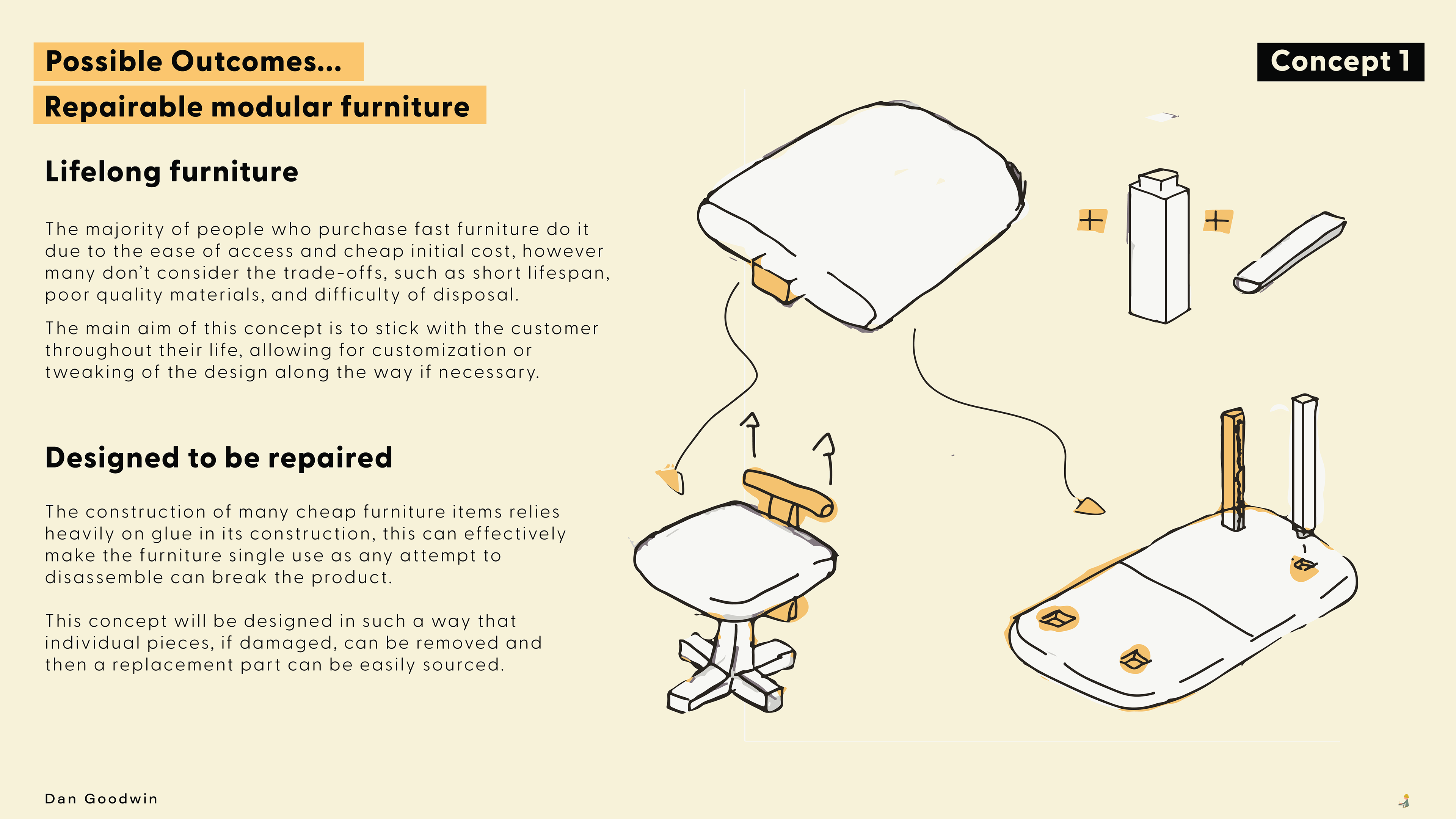

Adjustable's goal is to make furniture purchasing easier for frequent movers. Its modularity and flat-pack ability allows for easy and lightweight transportation. In addition the higher quality materials ensure there is a limited chance of breakage on each assembly or disassembly.

Components can be easily disassembled and flat-packed to ease transportation. Damaged components can also be easily removed and sent back to the factory, for a small fee, to be repaired, allowing for the product to hypothetically last forever.

The components shape was dictated by the need for individual parts to come together in two forms, this resulted in irregularities and potential imperfections in each format however also gives the product it's own unique identity.

Interlocking pieces allow for production from ones sheet of material, vastly reducing waste produced and production costs.

Development

At the start of the development process two CAD models were made for each form, each utilising the exact same components. This eased the creation of parts as joints could be pre-visualised before construction. Engineering drawings were then produced which were then used to create the physical components.

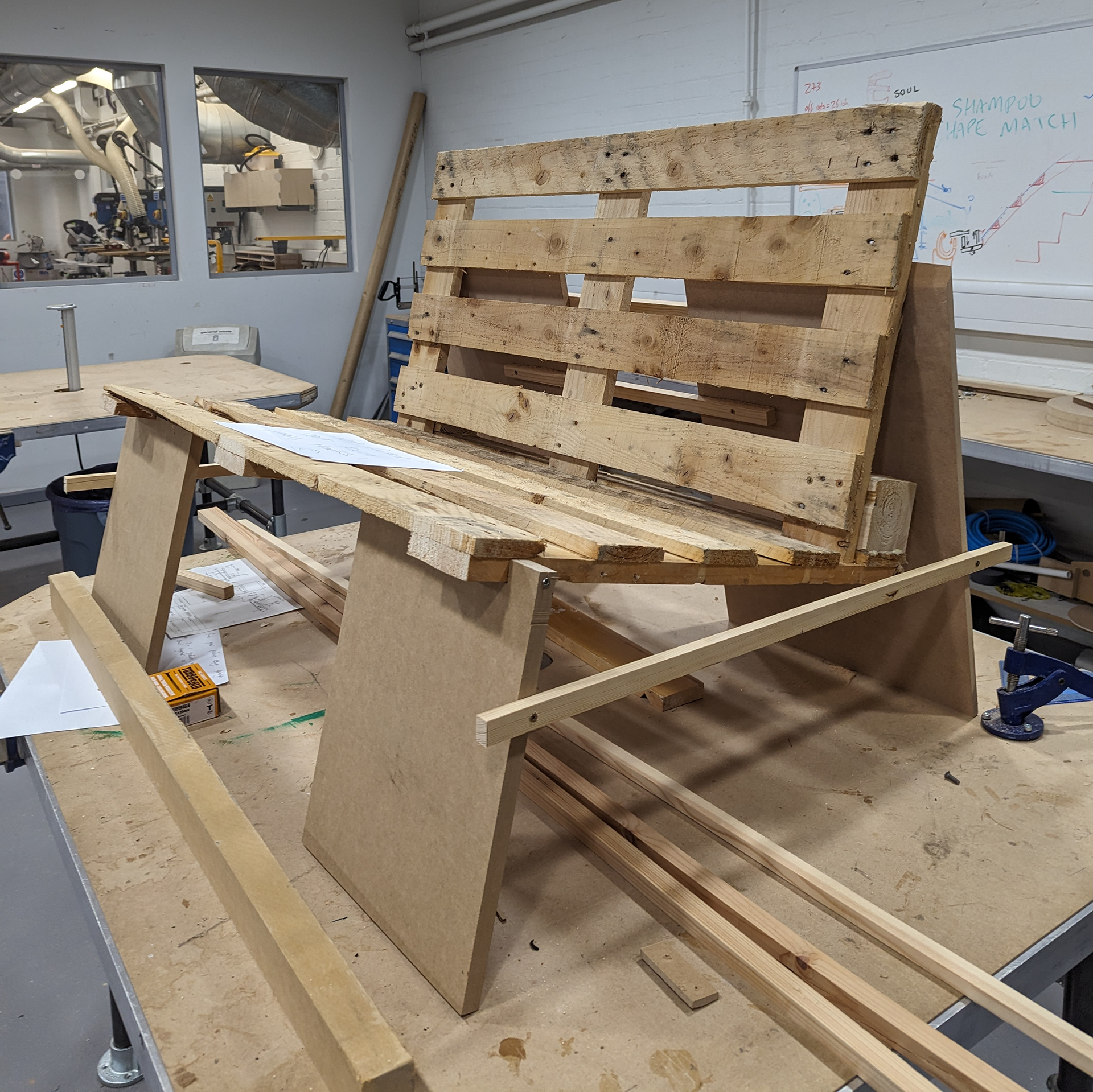

Test rig creation

Test rig Creation

Floor board processing: This involved de-nailing, cutting down to size and then planing.

Floor board glue up into individual slabs.

Slab processing: Utilising the CNC machine to create individual components. In total four slabs were cut creating four individual components.

Components were fine tuned using a chisel, creating angled cuts that weren't possible on the CNC.

Piece damaged during assembly, easily glued and repaired.

Part assembly.

Part assembly continued.

Part assembly different view.

Table assembly test.

Table assembly test different view.

Dowels added to secure construction.

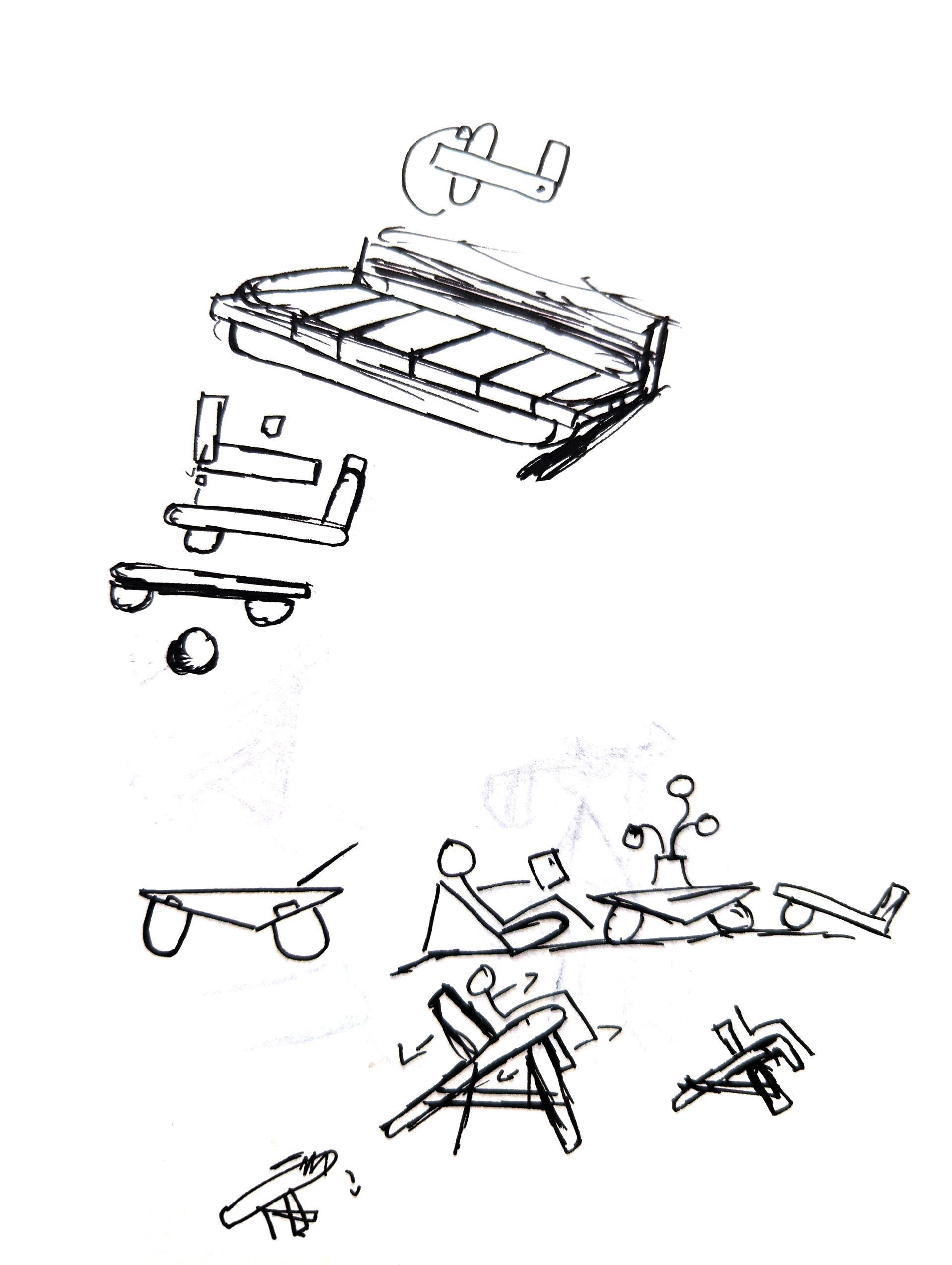

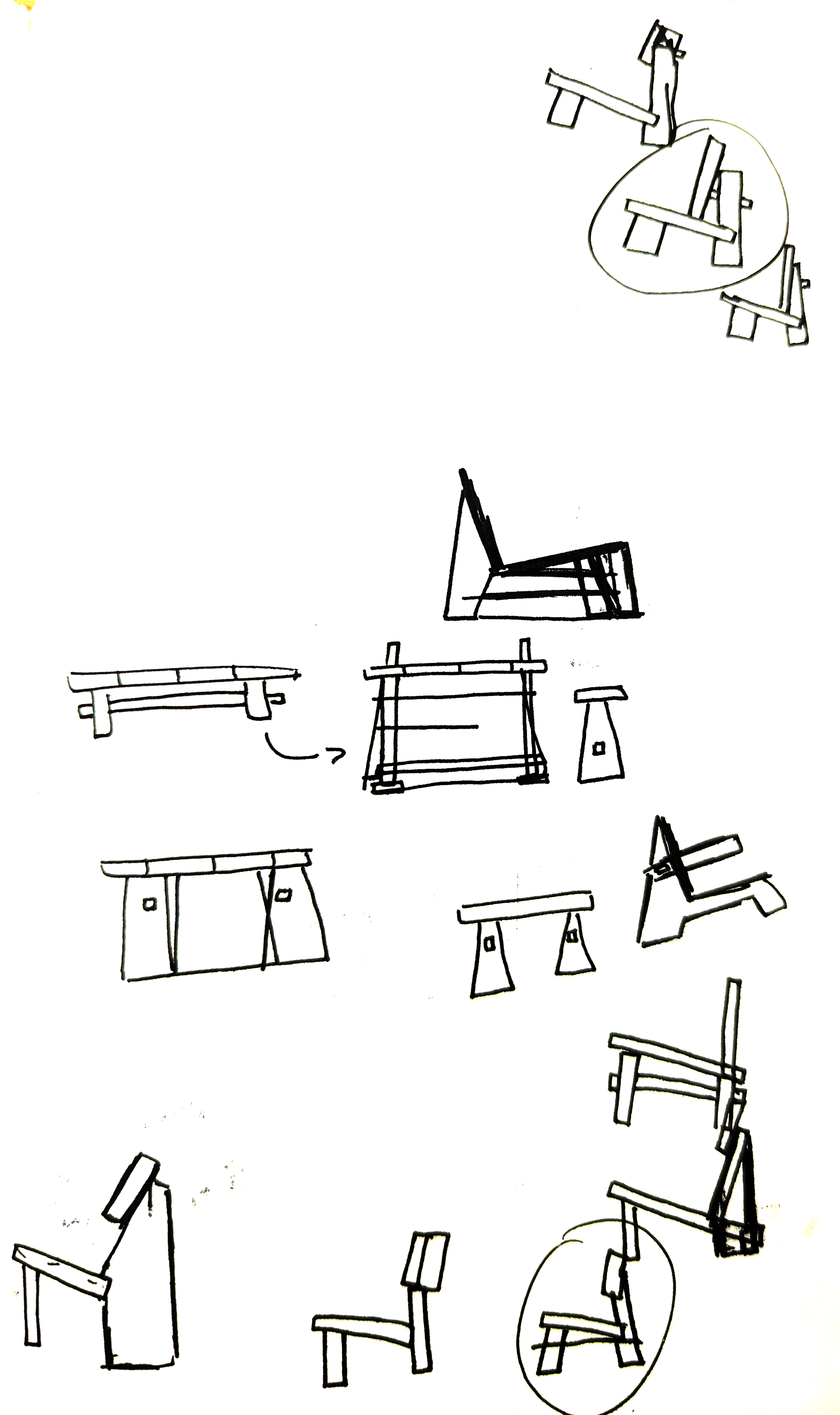

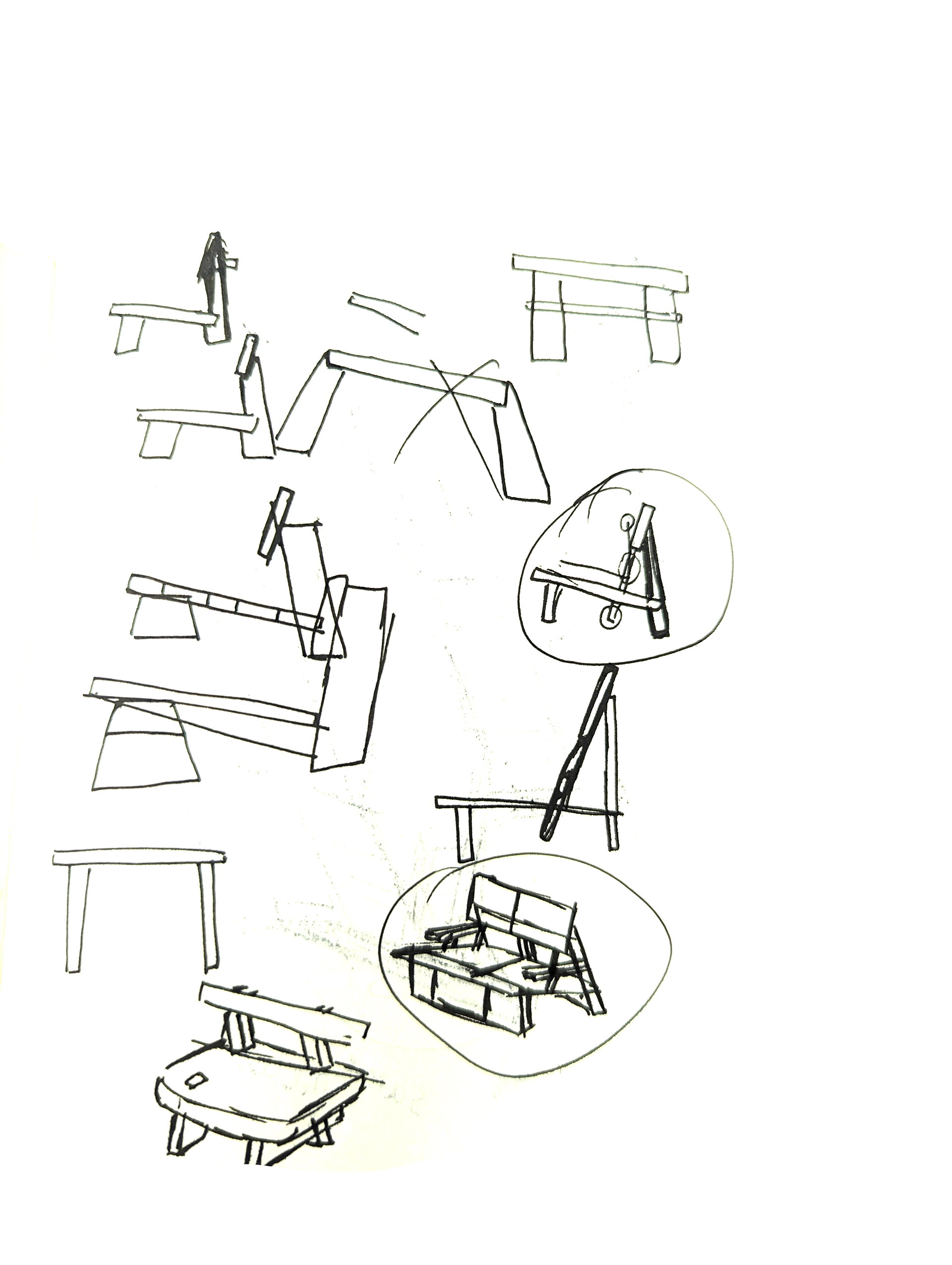

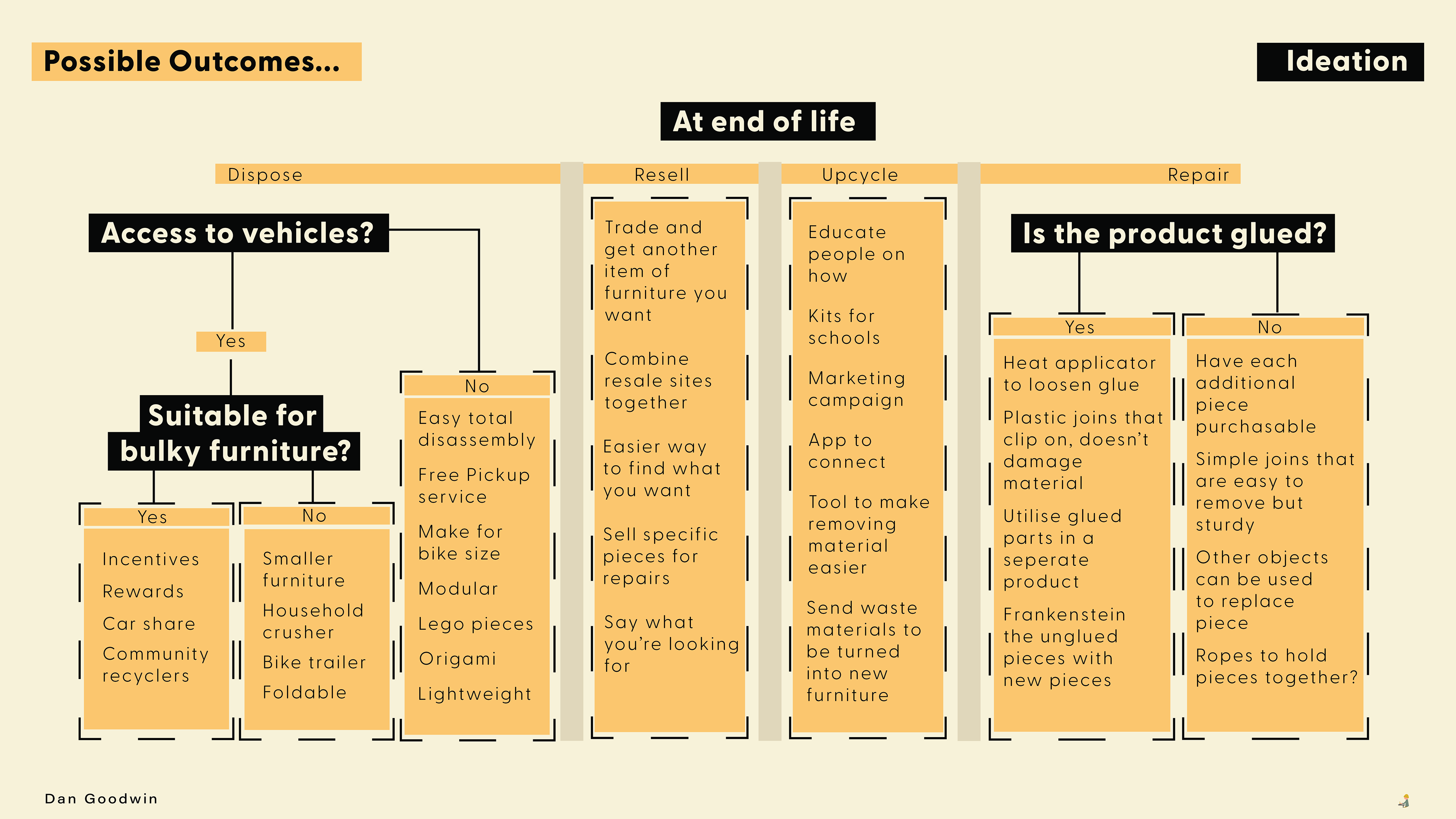

Concept Generation

Quick cardboard model that was referenced when creating the to scale CAD model.

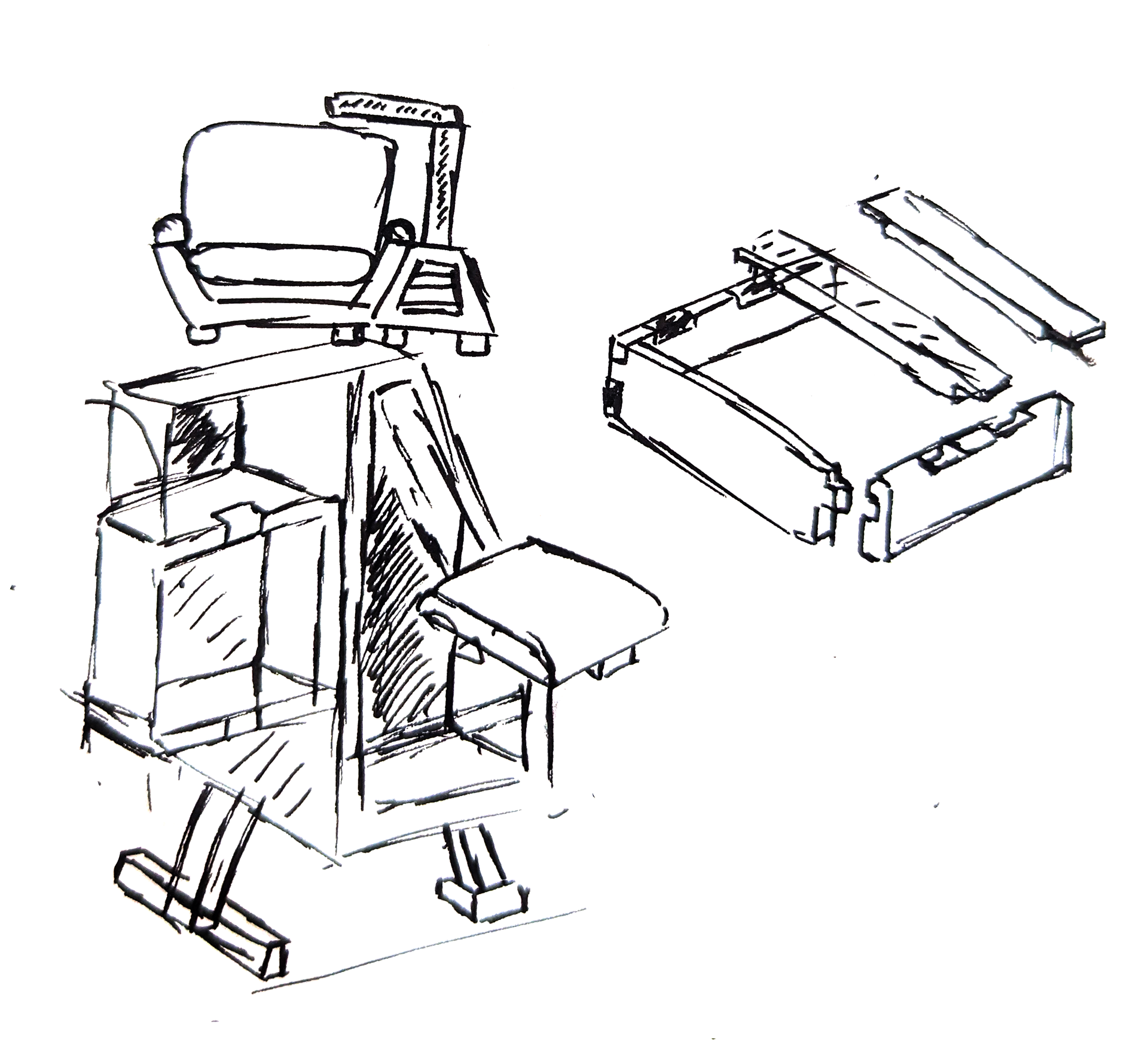

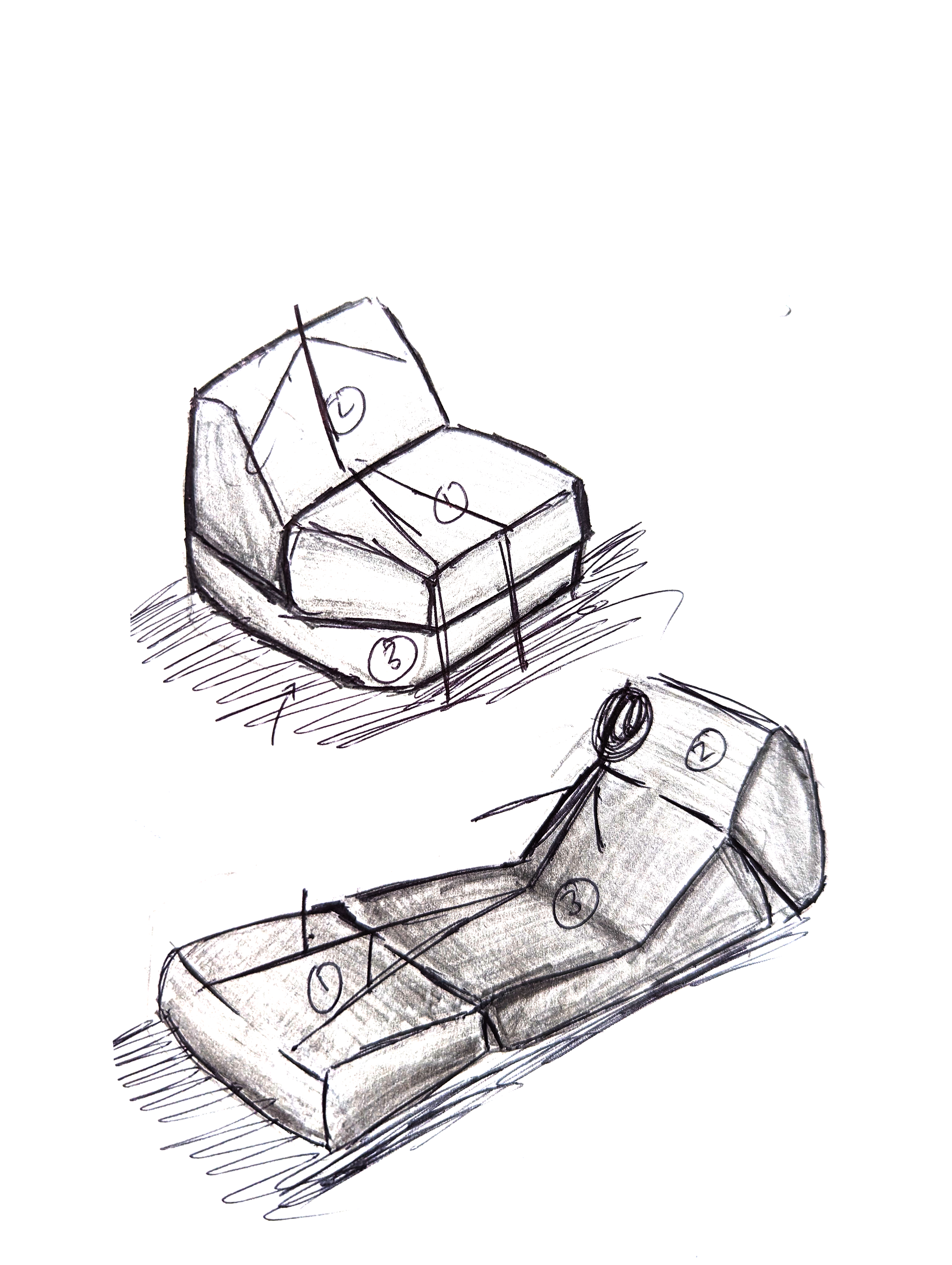

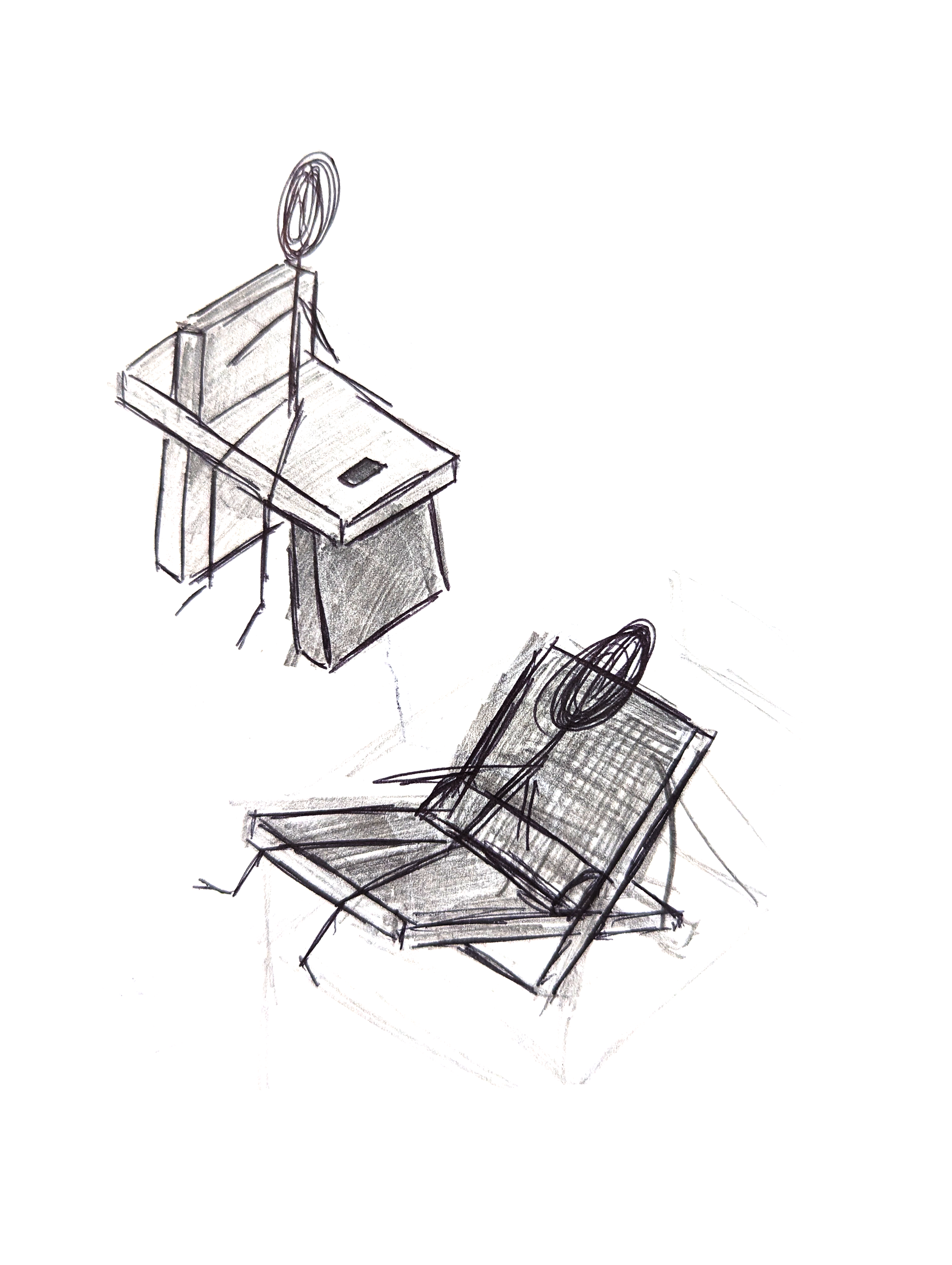

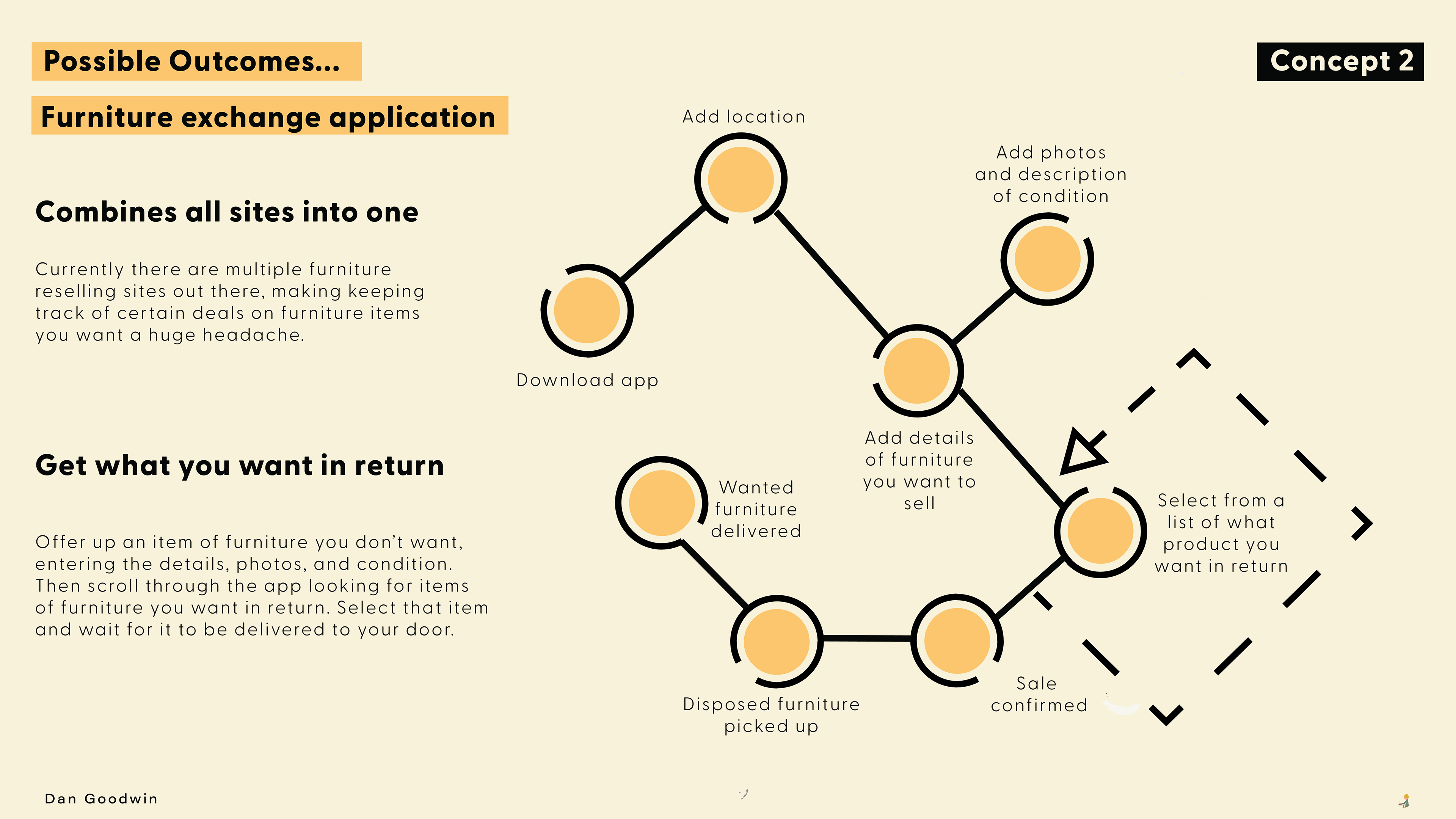

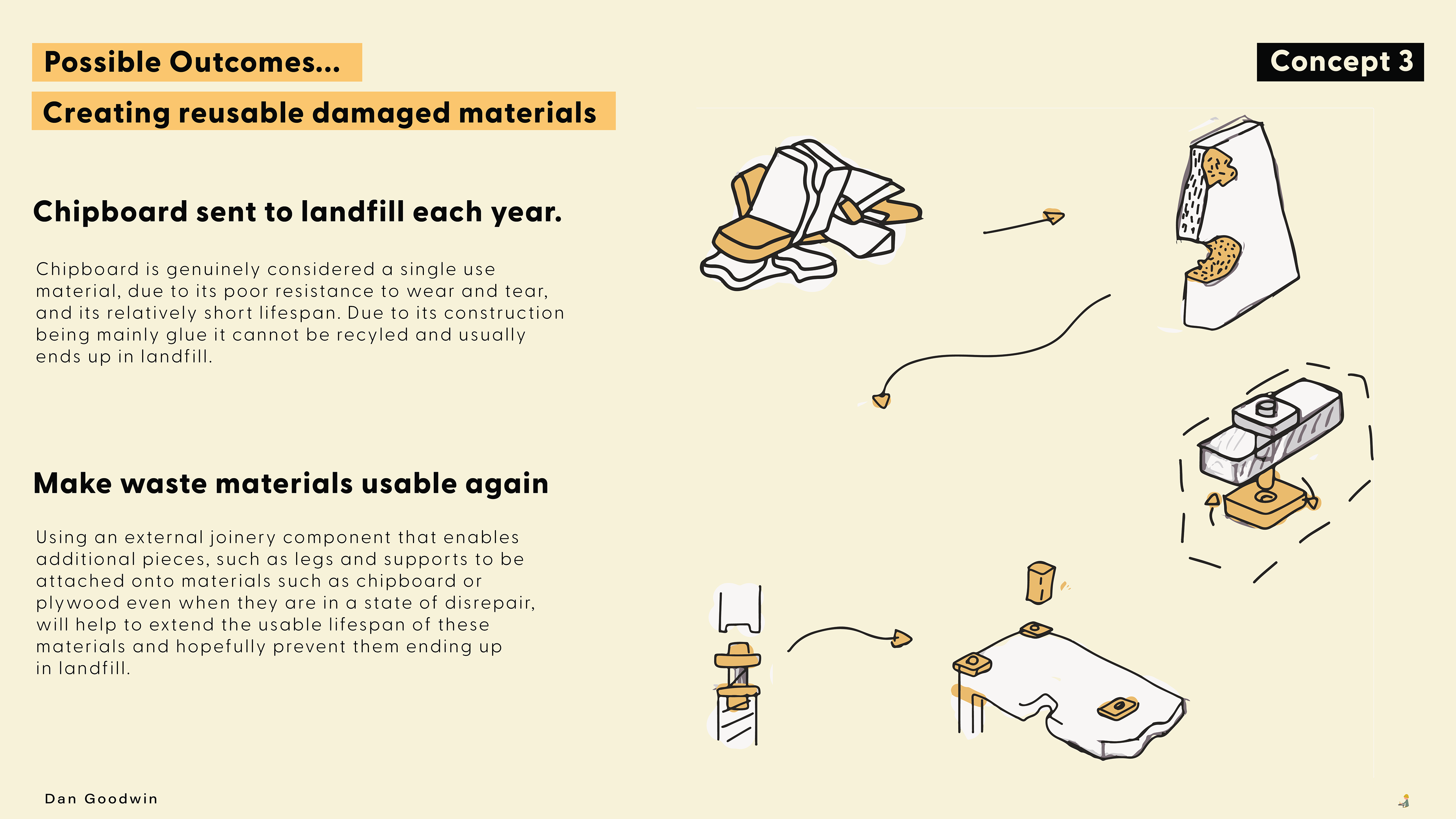

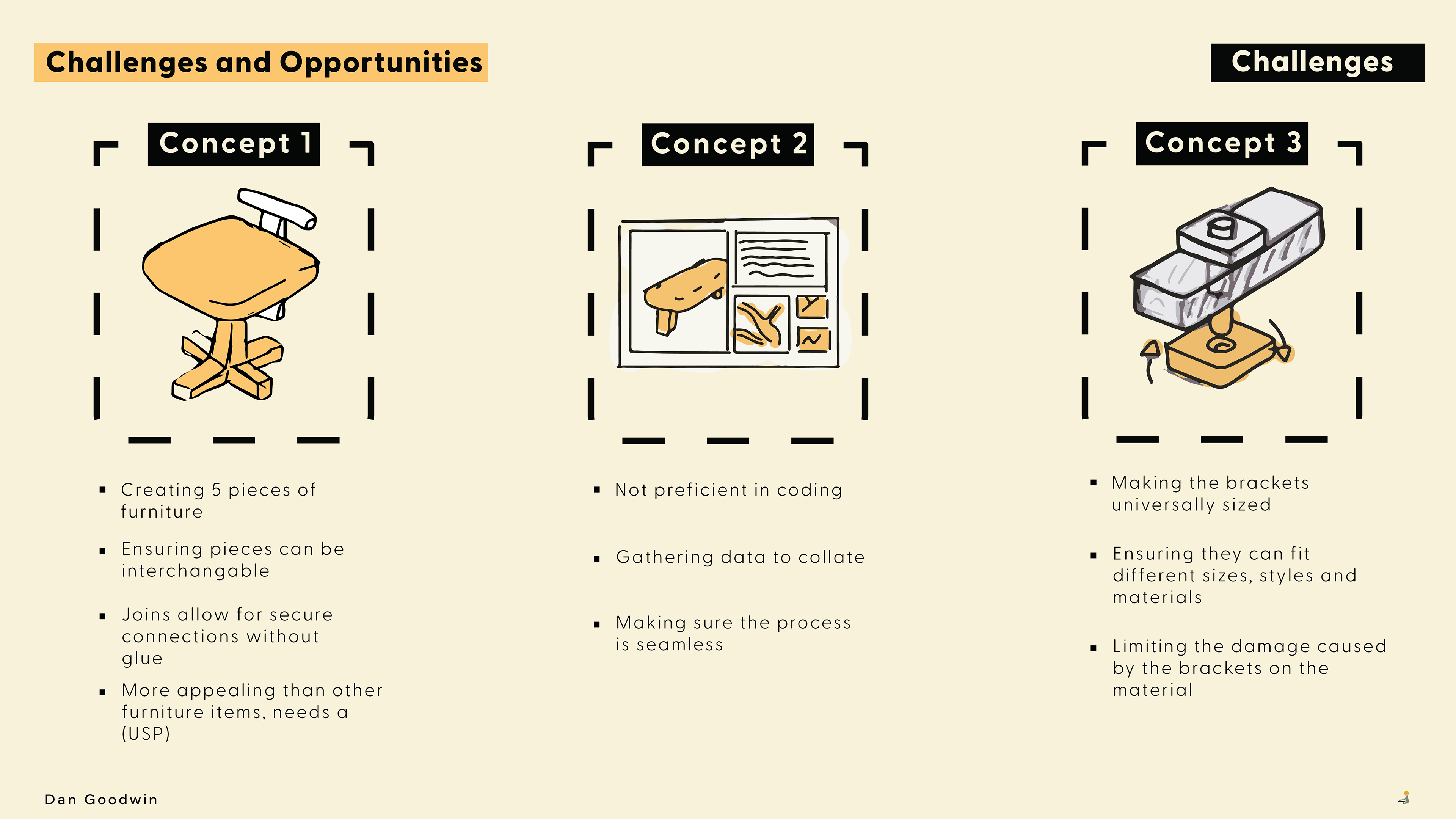

Three main conceptual ideas were singled out. An amalgamation of all three was chosen to take forward to the development phase.

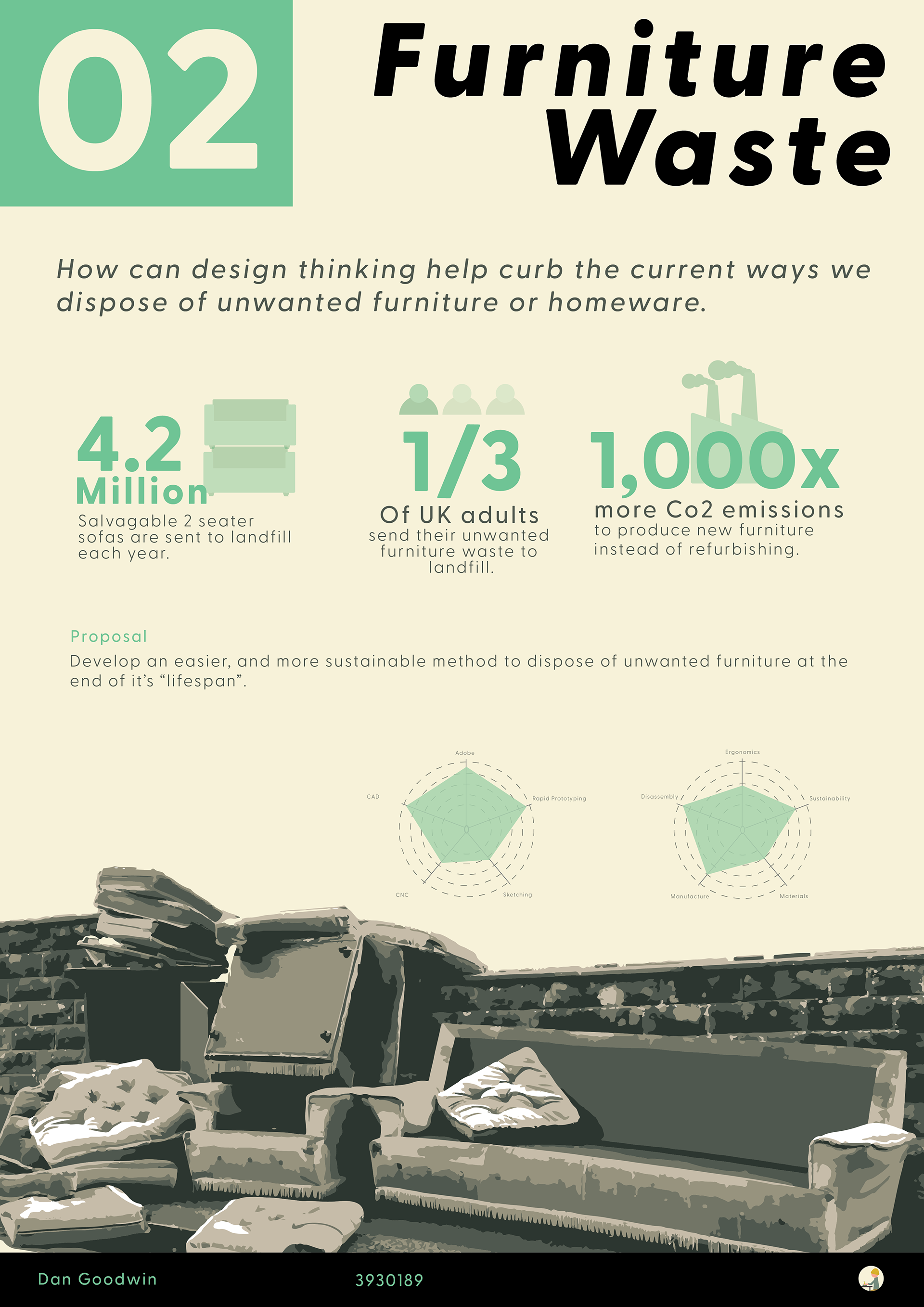

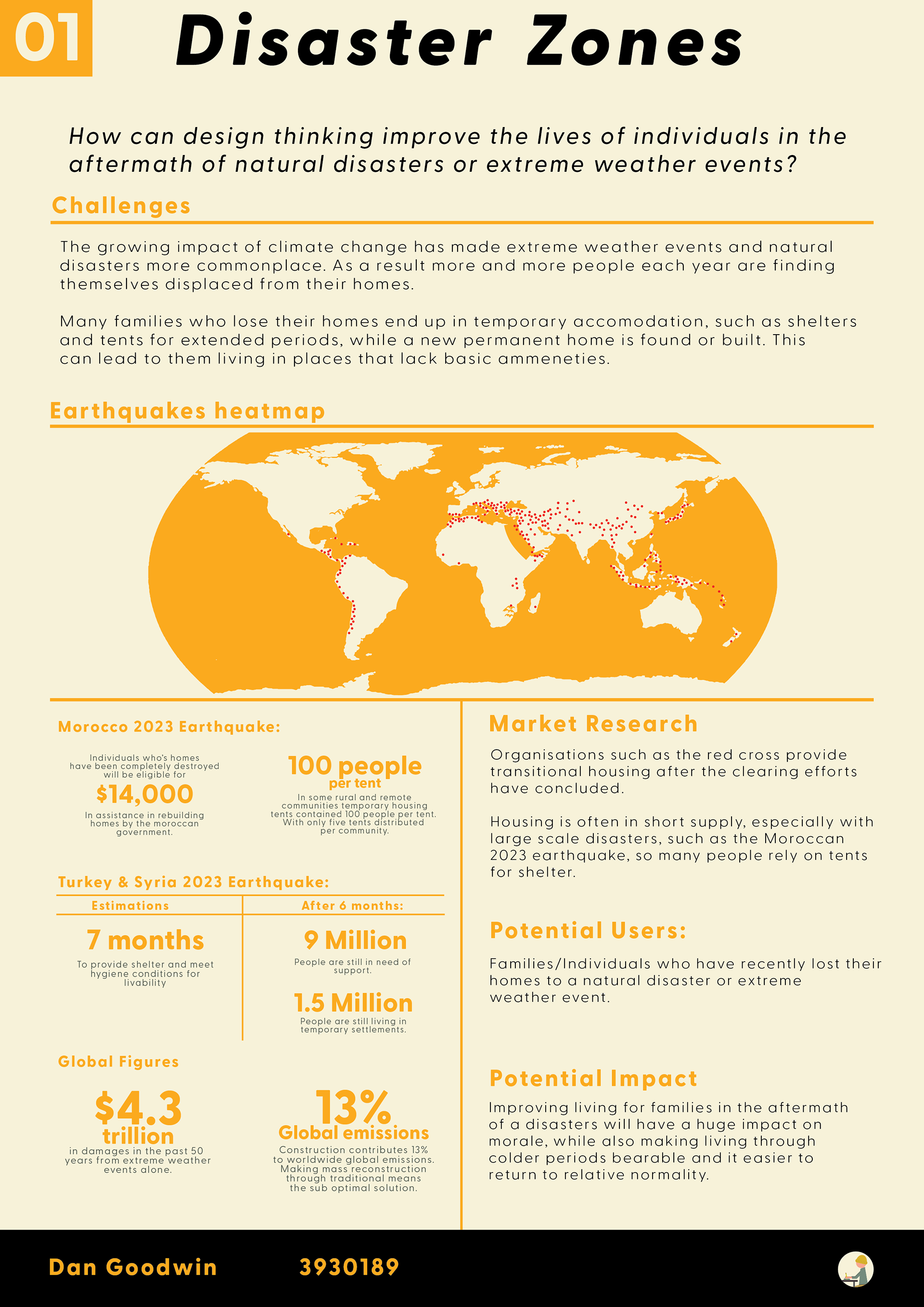

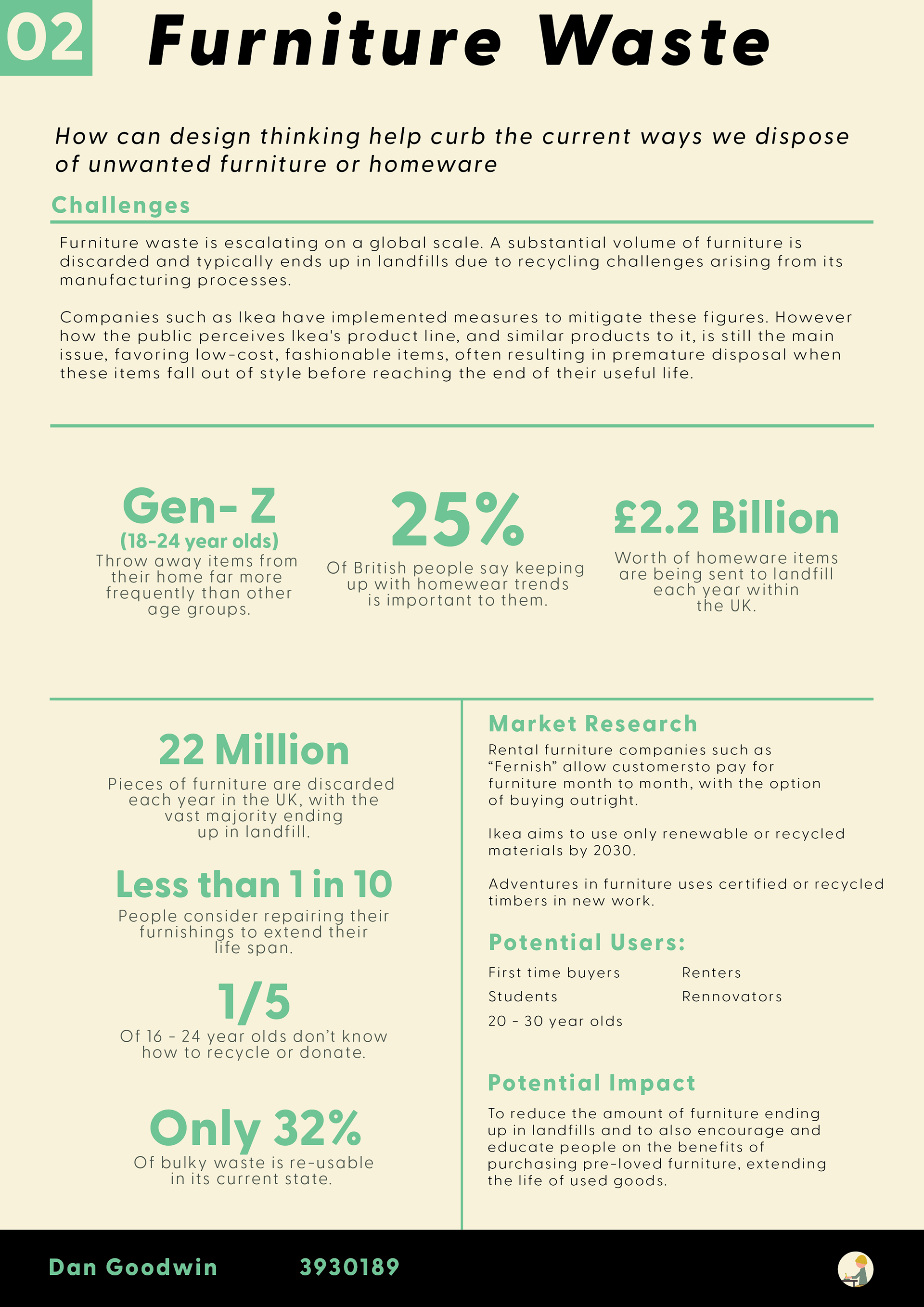

Research

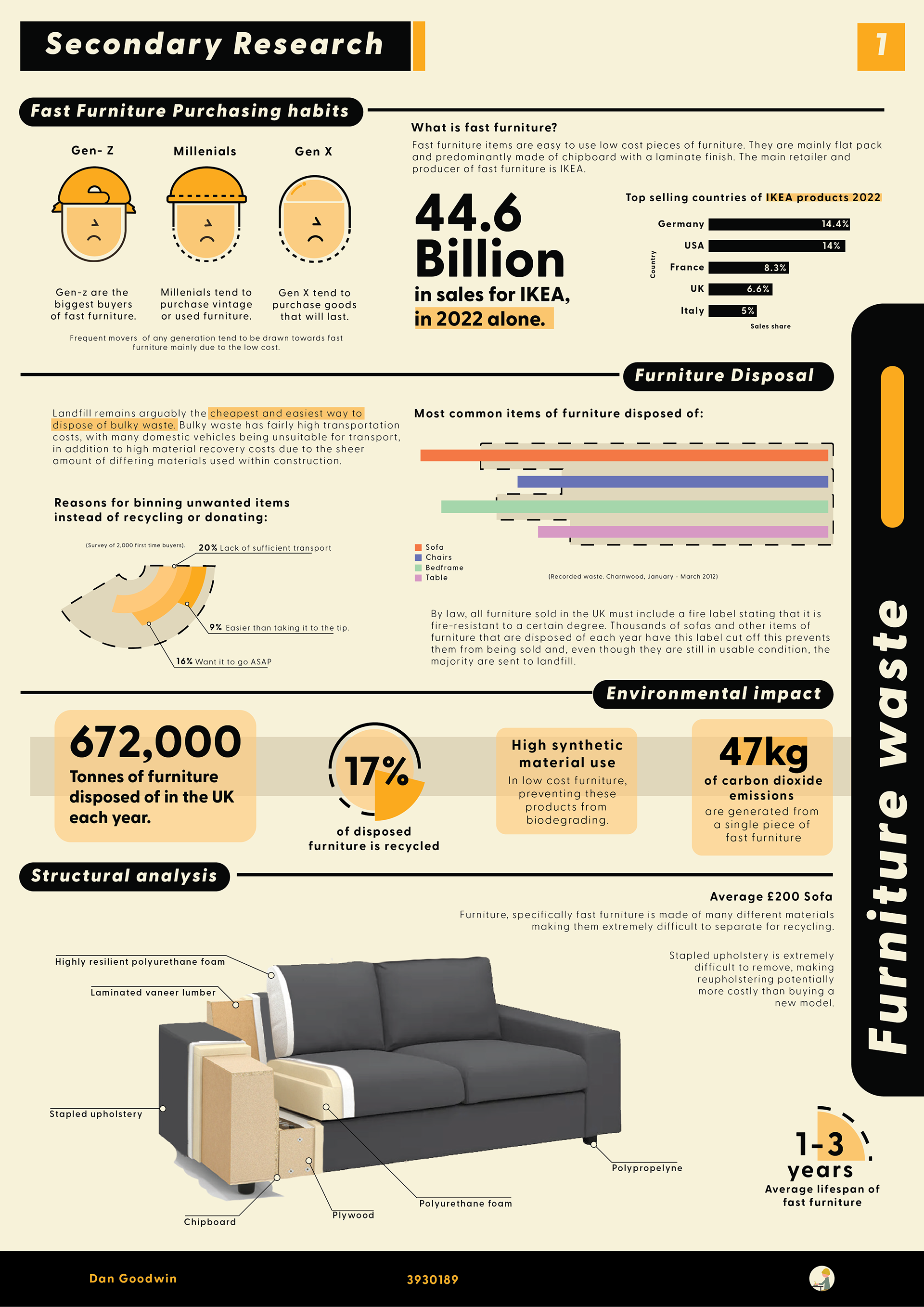

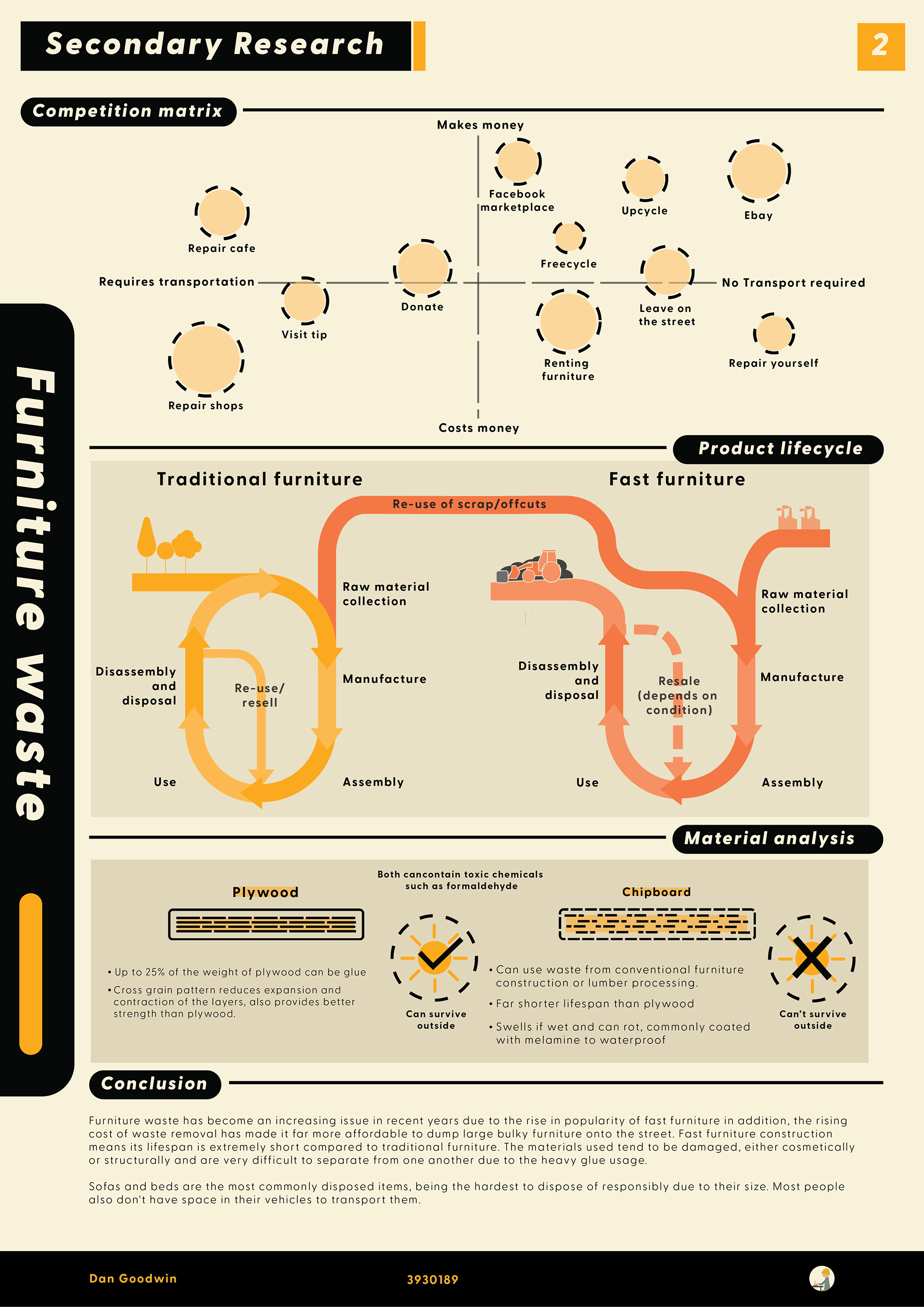

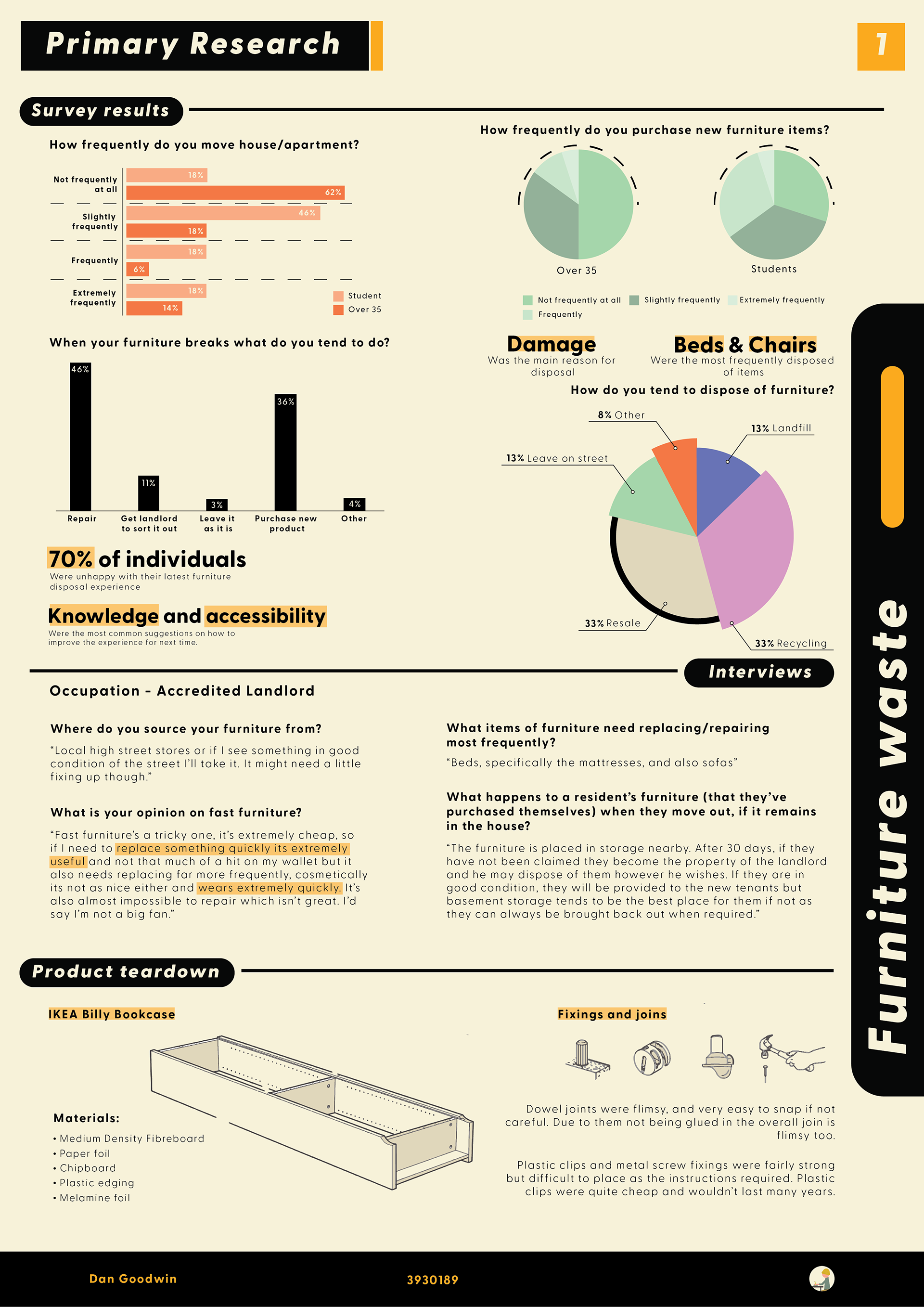

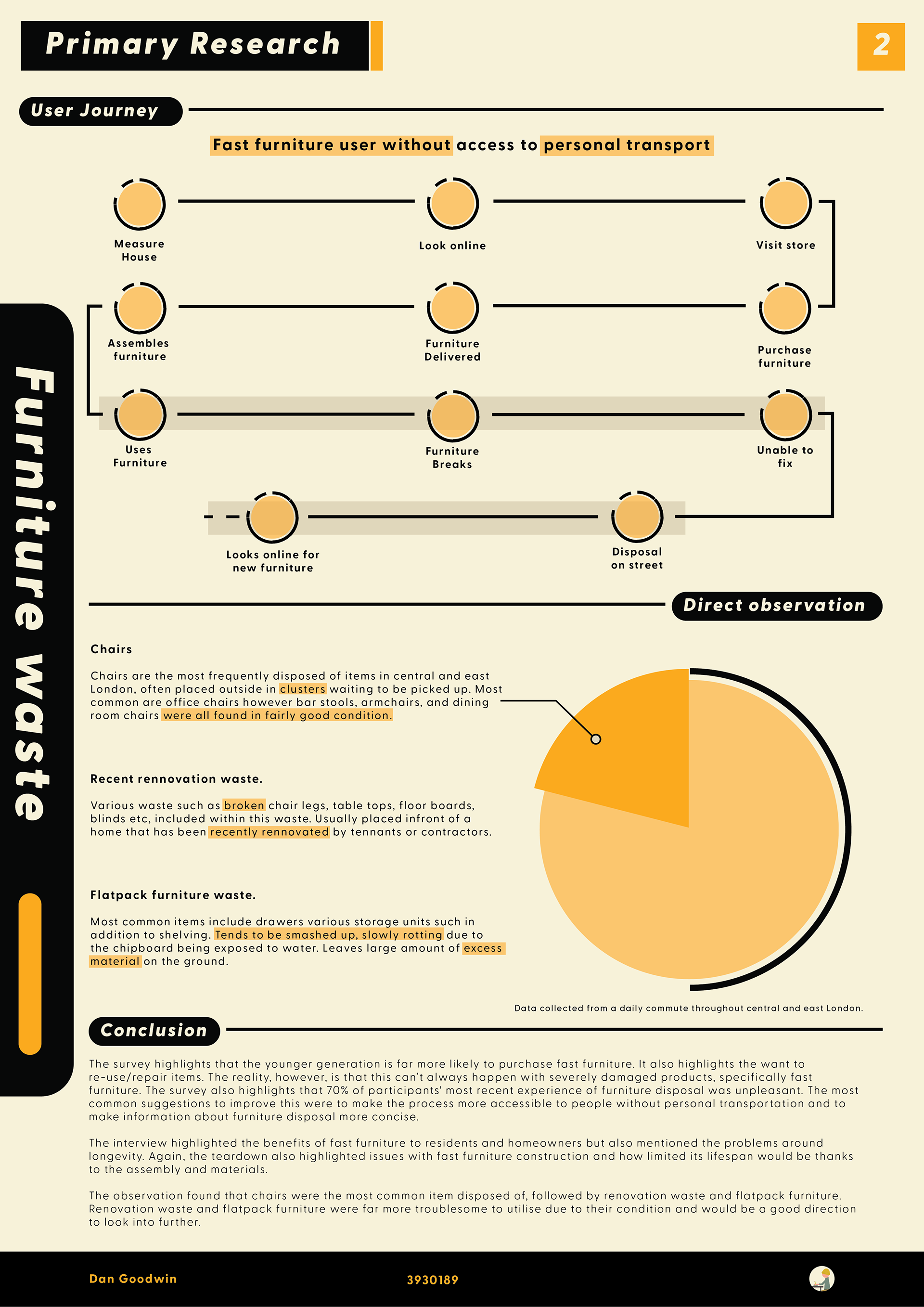

Primary and secondary research was conducted around the topic of furniture waste. Fast furniture was a particular topic of interest, specifically pain points and the predominant purchasers of these products. This information was then used to better inform concept development.